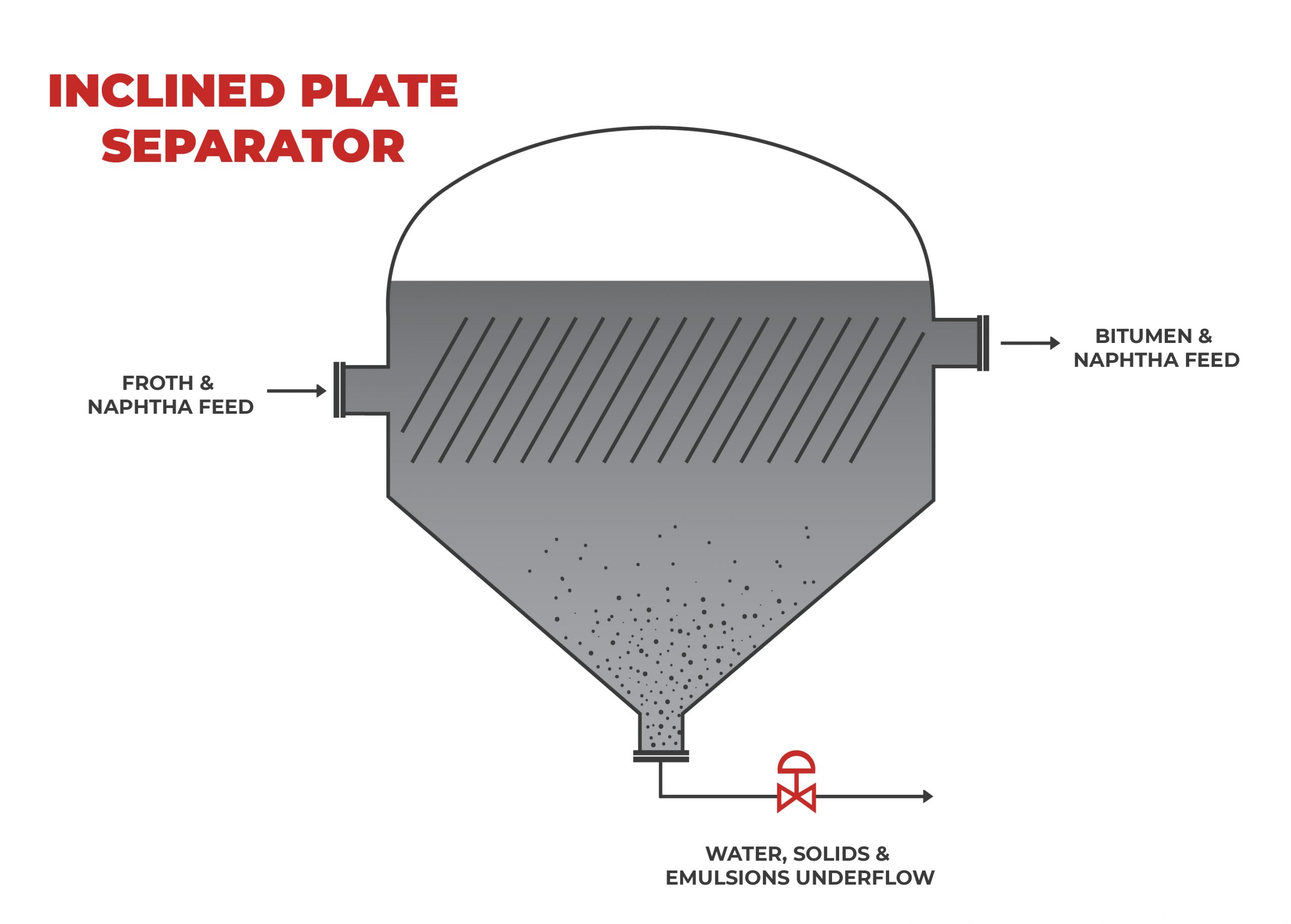

The problem: Pipe and Control Valve Erosion

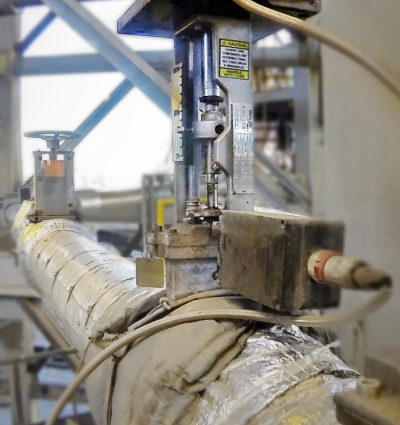

Oil sands facilities that use separation equipment (such as IPS) often deal with severe erosion to their underflow control valves and downstream piping.

In some scenarios, these components require replacement every 4 months.

The Solution: SlurryFlo Control Valves

SlurryFlo’s patented valve technology provides a quantum leap in service life (>10X). In the IPS underflow case, control valve service life increased from 4 to 36 months of continuous operation. Our client now enjoys reduced maintenance costs, greater profits, and significantly fewer shutdowns

SlurryFlo control valves offer several advantages for any severe oil sands service:

- 3-10x longer service life.

- Reduced maintenance costs.

- Field replaceable wear components.

- Flow control experts that will provide the best solution, with ongoing support as conditions change.

The SlurryFlo control valve sells itself – It just works!

– Senior Facilities Engineer, Bitumen Production

Athabasca Oil Sands Mine, Fort McMurray

Continued Support

The engineering team at SlurryFlo provide ongoing engineering service and support. This ensures a cost effective, adaptive solution that manages pressure drops and reduces cavitation as flow conditions change.

Here at Summit, we work closely with SlurryFlo to simplify communications and ensure you get the most out of your control valve.