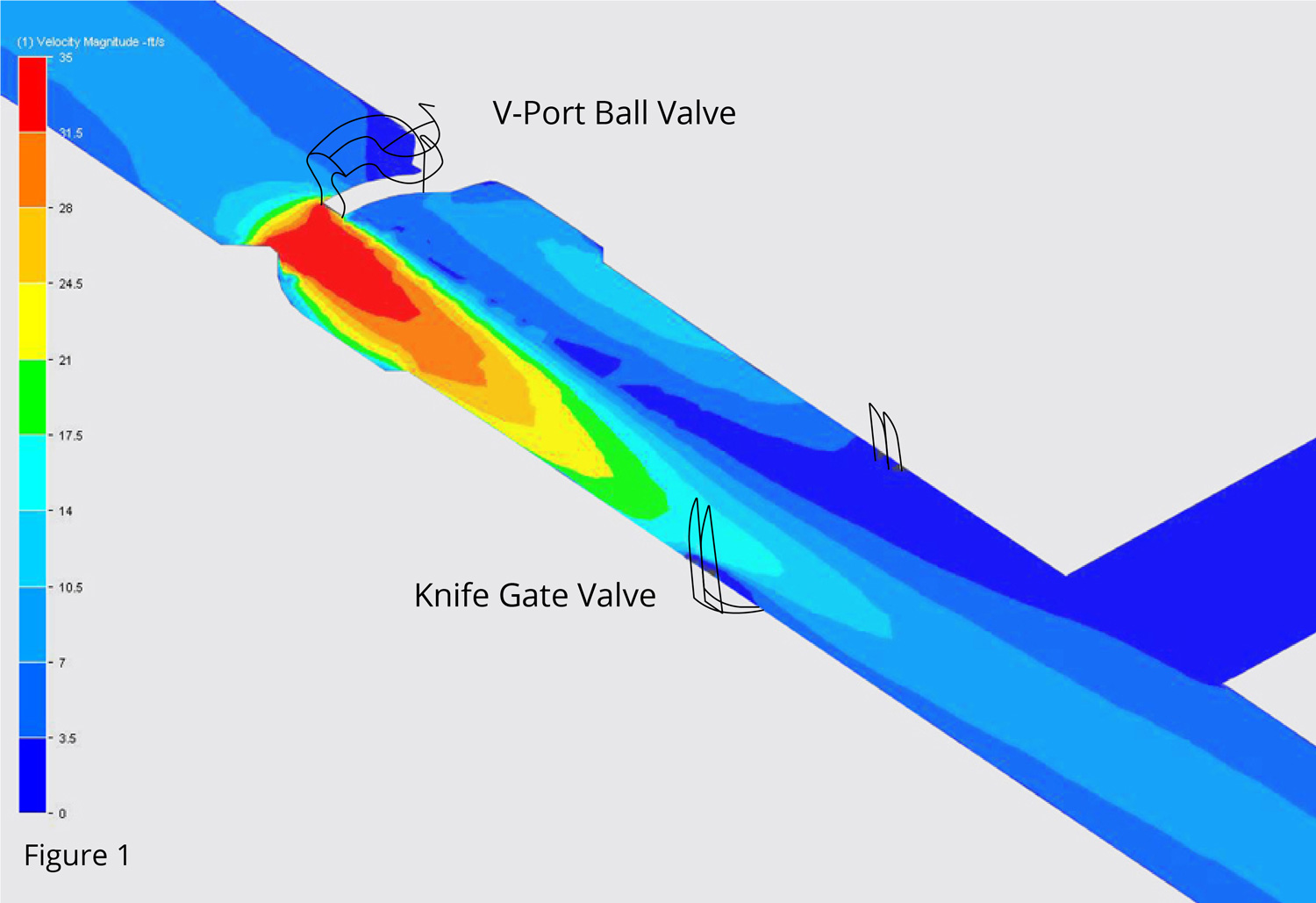

The problem: Severe erosion of V-Port Ball Valve

When throttling v-port ball valves, high-velocity flow is projected towards the valve body and downstream piping, eroding both. Severe erosion to the ball valve results in the inability to effectively modulate flow.

This can lead to high maintenance costs associated with replacing eroded piping and damaged downstream valves unable to provide a tight shut off.

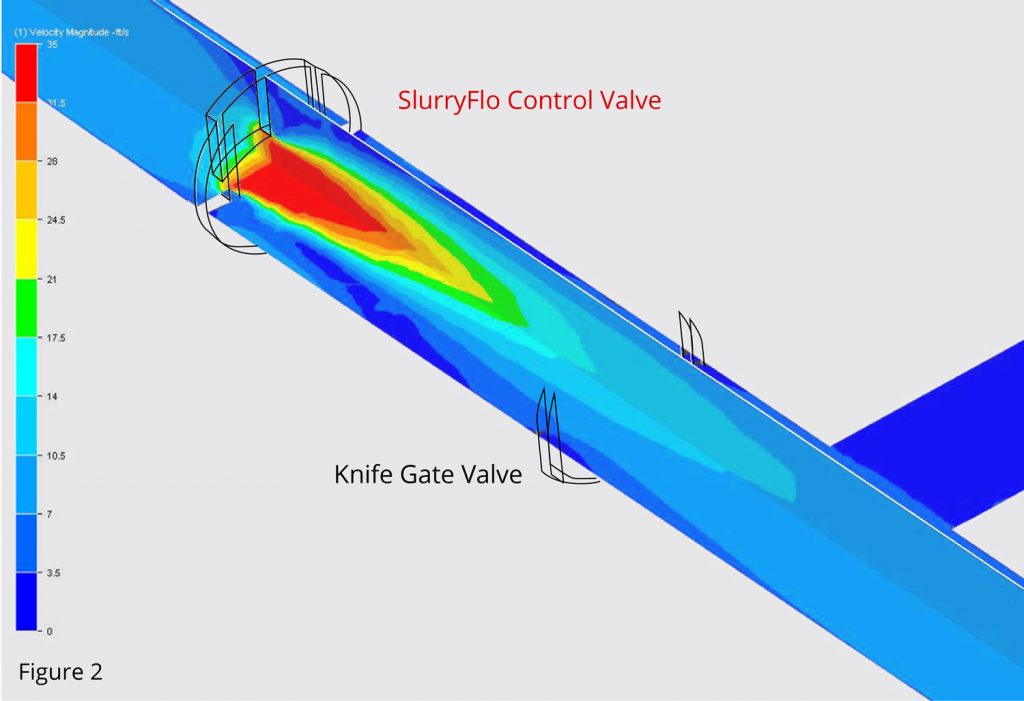

The Solution: SlurryFlo Control Valve with variable orifice

The SlurryFlo control valve patented trim design acts as a variable orifice, centering the abrasive froth slurry within the pipe. Centering the flow results in reduced wear in the valve trim. With reduced wear, the downstream piping condition and critical shut-off capabilities are maintained.

With only trim components exposed to erosive flow, the service life of the valve is greatly extended. These parts do eventually wear out, but can be replaced on site, extending the service life for a fraction of the cost of a complete valve replacement.

This solution has proved to increase the service life from less than 6 months to over 3 years. That’s a 600% improvement!

Continued Support

The engineering team at SlurryFlo provide ongoing engineering service and support. This ensures a cost effective, adaptive solution that manages pressure drops and reduces cavitation as flow conditions change.

Here at Summit, we work closely with SlurryFlo to simplify communications and ensure you get the most out of your control valve.